About us

ORIGINS OF

1997-1999

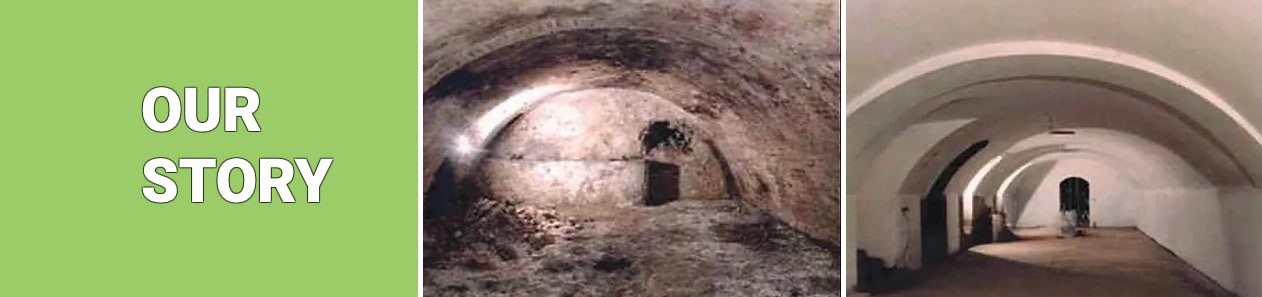

Year 1997 is considered as unofficial start of our company. Idea to start was based on huge problems during severe storms and floods in Central Europe. Water entered structure of buildings and remained trapped inside. That caused serious problems with statics together with severe health hazard due to creation of molds and fungi. When we studied existing and available products, we found out there is no functional solution to solve this problem. Analyzing why available solutions were not functional, we discovered one specific reason of failure. All existing waterproof products were based on film-forming membrane with rubber-like consistence.

Our team has identified single crucial point. In order to make waterproof product which is able to be absolutely 100% functional for at least 1 year period, it must solve the problem with trapped moisture at the same time. We set the target for new product and started to work. In 1999 we built our first factory in Slovakia, we created first generation of IZONIL and our company IZONIL GROUP started officially.

TESTING IN REAL-LIFE CONDITIONS

2000 - 2010

In first year we have defined 3 key objectives: 1) Product must be breathable, 100% waterproof and able to dry the moisture out of the wall. 2) We must be able to guaranty 100% functionality of the product for at least 10 years. 3) We must be able to ensure low price in long-term horizon. In 1999 we built first factory in Slovakia. In 2000 we have started serial production with main target to expose our product to real-life conditions because laboratory tests alone do not reflect real-life conditions. In 2010, after 10 years of testing the product in real-life conditions mostly in Central Europe, together with our customers we were able to confirm that IZONIL waterproof drying system (WDS) meets all 3 key objectives defined in 1999.

GLOBAL PRESENCE OF

2011 - up to this day

After 10 years of testing in real-life conditions, IZONIL waterproof drying system (WDS) confirmed its 100% functionality. In next step, we have started to implement strategy of global presence. In 2011 we built our factory in Vietnam. In 2014 we built factory in India. In 2015 our partner built factory in China based on our know-how. Currently IZONIL products are being used in Asia (China, India, Vietnam, Philippines, Thailand, Indonesia, Malaysia, Brunei, Bangladesh, Singapore, Hong Kong and others) and in Europe (Slovakia, Hungary, Germany, Austria, Czech Republic, Poland, Lithuania, Luxembourg, UK and others). We keep working hard to make IZONIL available in new countries.

MOISTURE ENTRAPMENT

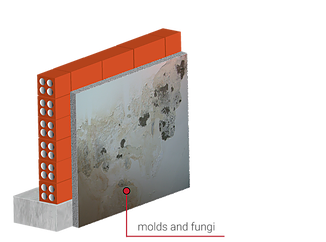

GLOBAL PROBLEM IN BUILDING CONSTRUCTIONEvery building has natural need to breathe. If this need is not addressed, problems start. Examples are all around. Paint and coating peeling off. Plastering mortar falling off. Steel reinforcement corroding. Building materials disintegrating. Molds and fungi growing.

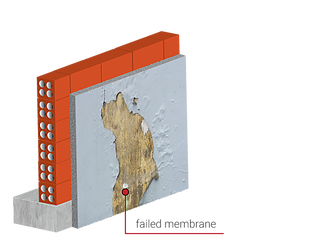

Take an example of photos above. First is international airport in Manila, Philippines. Second is 5-star hotel resort in Da Nang, Vietnam. Third is new hospital in Shandong province, China. Millions of buildings around the world have the same problem. The reason is moisture trapped within the building structure. Buildings are usually coated with synthetic waterproof membranes.

Synthetic waterproof membranes are not equipped to deal with the moisture inside the building structure because they are not breathable. Due to inability of membrane to breathe, moisture remains trapped within the building structure being physically unable to evaporate through the membrane. In result, moisture mechanically destroys membrane from negative side.

If we use water vapor diffusion coefficient (µ-value) to quantify breathability, various types of membranes have µ-value in thousands (in general 5 000 - 100 000 depending on specific kind of membrane). Materials considered breathable and thus suitable for renovation purposes according EN standards must have µ-value ≤ 15. In other words, waterproof membranes are hundreds and thousands times less breathable than materials considered as breathable.

Toxic molds are the most dangerous consequence of trapped moisture. Humidity within building structure is ideal environment for molds to grow, colonize, reproduce and spread. Molds contamination in humid buildings leads to multi-system health problems. There are thousands of articles, studies, books and papers written on this topic. Research is very clear about negative effect of molds on human health. Molds in buildings are quiet worldwide epidemic.

Disintegration of building materials is yet another result of moisture entrapment. In case of non-load-bearing materials, the result is desolate state of building facades with surface of walls falling apart. Buildings have horrible appearance and their value depreciates. Renovations on regular basis are expensive, time-intensive and annoying.

Corrosion of steel reinforcement is even more dangerous because it is load-bearing element directly related to statics and long-term safety of buildings.

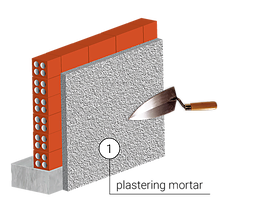

/ REPLACEMENT OF PLASTERING MORTART

Made of binder (cement), filler (sand) and natural additive (Izocomponent) in fully-computerized drymix process, our product replaces plastering mortar. It substitutes both external (rendering) and internal (plastering) purpose of ordinary plastering mortar, either it is traditional "sitemix" plaster (made by manual mixing of cement and sand at construction site) or modern "drymix" plaster (factory-made mixture of cement, sand and chemical additives).

IZONIL is easy to use. Builders skilled in application of ordinary plaster are able to use IZONIL waterproof drying system (WDS). Mixing of IZONIL requires only addition of water and application requires the same set of tools which are normally used for plastering.

/ 100% WATERPROOF SYSTEM

IZONIL is 100% waterproof in all thickness. It is fully functional barrier against water penetration without additional waterproof membrane.

It is applicable on both positive and negative side and resists hydrostatic pressure both from positive and negative side with water penetration less than 1 mm (tested according EN 12390-8 with water pressure 1 BAR / 0.1 MPa).

Some of our products (available in Asia) are developed to be 100% waterproof when exposed to heavy monsoon rain but not suitable to be used on negative side to withstand hydrostatic pressure (more details in products).

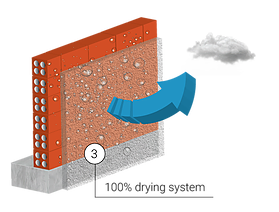

/ 100% DRYING SYSTEM

IZONIL has ability to constantly dry the moisture from the substrate (wall or concrete slab). 100% drying system is active physical process of pulling out the moisture from damp substrate and transferring it on molecular basis in form of vapor through layer of IZONIL further to outer environment.

This is possible due to extreme breathability of IZONIL. Requirement of water vapor diffusion coefficient (µ-value) for renovation (R) plastering mortars according EN 998-1 is ≤ 15. Renovation (R) plastering mortars have µ-value within range 10-15. IZONIL has µ-value < 8.

Impact of 100% drying system on the building is essential. IZONIL is able to solve the problem with trapped moisture for conventional building made of concrete and bricks or blocks.